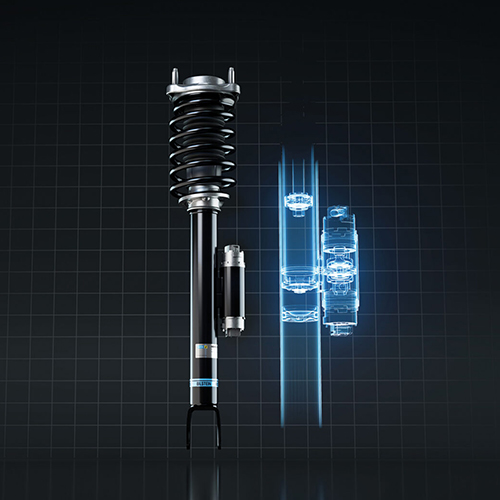

Where quality meets verification: the 7-post test rig from BILSTEIN

Four hydraulic pistons under the wheels, three additional ones on the vehicle body. Sensors at all relevant points: using the 7-post vertical dynamics test rig at the BILSTEIN Competence Centre at the Nürburgring, engineers analyse the handling characteristics of an enormous range of vehicles. This provides a reliable basis for quality that customers worldwide can rely on.

At BILSTEIN, quality is created through a comprehensive system of simulations, test rigs, vehicle tests and laboratory analyses. One important tool in this process is the 7-post vertical dynamics test rig. ‘Our 7-post allows us to specifically induce vertical road surface vibrations, body movements such as pitching and rolling, and additional loads,’ reveals Andreas Simon, motorsport test engineer at BILSTEIN. This makes it possible to simulate specific test tracks and even entire race tracks.

The test rig thus makes it possible to analyse the interaction of damping, suspension and vehicle body under defined conditions. Changes to valve characteristics or suspension configurations can be specifically investigated and directly compared with each other. This reveals how individual adjustments influence overall behaviour – not in isolation, but in the context of the complete vehicle.

Many of the methods and evaluation criteria used on the 7-post originate from projects with leading car manufacturers and the motorsport environment. Where demands are high and decisions have no second chance.

Systematic analysis of vehicle dynamics

For car drivers, this means one thing above all else: shock absorbers and suspension systems whose performance is not based on subjective assumptions, but is objectively and systematically verified. Their tuning responds in a controlled manner to uneven surfaces, remains stable during rapid load changes and behaves predictably in situations where comfort and driving stability are required at the same time. The result is a consistent, balanced driving experience – regardless of whether you are on long motorway journeys, poor roads or in dynamic driving situations.

The special added value of the 7-Post lies where comparability is crucial. Tests can be repeated identically, parameters can be changed specifically and results can be compared objectively. ‘I replicate the vehicle on the test rig as it would drive on a real road or track, but under controlled conditions,’ says Andreas Simon. ‘We have no temperature fluctuations, no weather influences, and we can replicate these test scenarios over and over again.’ This makes the test rig an important addition, especially where developments are being systematically investigated.

This also applies to the aftermarket sector: the expertise gained on the 7-post is consistently transferred to BILSTEIN’s performance and OE replacement products. Findings from the precise analysis of vehicle movements help to tune suspension systems so that they react in everyday use in the same controlled and predictable manner as they do under extreme conditions.

Testing as a continuous learning process

At BILSTEIN, testing is not an approval process at the end of development. It is part of a continuous learning process. On average, several dozen structured test scenarios run on the 7-post every week. Not as individual events, but as building blocks of a growing wealth of experience.

Over the years, BILSTEIN has built up its own catalogue of several dozen standardised test scenarios, supplemented by project-specific applications. These scenarios are documented, further developed and used across different vehicle projects. Quality is not created here in individual tests, but through the ability to classify results over time and across projects.

This allows for development that is not based on snapshots, but on reliable comparisons. Assumptions can be verified, concepts confirmed or rejected. Quality is therefore created where decisions are based on comprehensible results.

Several thousand measurements per year

No surprise that the high-performance test rig is working at full capacity. Every year, loads of road test data goes into developing and tuning suspension systems and shock absorbers: several thousand individual measurements are recorded, analysed and archived each year.

This is the responsibility of small, highly specialised teams who oversee the test benches, simulations and road tests. Engineers with experience in OE development and motorsport who not only measure but also interpret. They are the ones who ensure that the full potential of the test rig is unlocked. After all, the rig only reveals its full value when the data obtained is interpreted correctly.

says Andreas Simon ‘At the end of the day, a test bench is just a machine. It doesn’t do anything on its own. The decisive factor is always the development and engineering work and the expertise behind it.’

Quality is only achieved by classifying the test rig data provided. Through experience, through understanding of the system and through the ability to translate technical results into concrete development decisions.

Understanding shock absorbers and suspension systems better and faster

Another key aspect of the work carried out on the 7-Post is efficiency. The vertical dynamics test rig makes it possible to compare a wide range of setups, scenarios and variants within a very short time. ‘We quickly reach our limits on the track,’ explains Andreas Simon. ‘On the test bench, we can compare significantly more variants under identical conditions and make a clear comparison. This helps us to understand more quickly which changes really make a difference – and which do not.’

This makes the 7-post test rig an important part of the testing and development work at BILSTEIN, making a valuable contribution to the quality of BILSTEIN products.

Our cutting-edge valve technologies and damping systems – from active to passive – guarantee unrivaled top performance and reliability. We bring premium OE quality to the aftermarket, making testing easier and ensuring your success every day.

Discover the technology