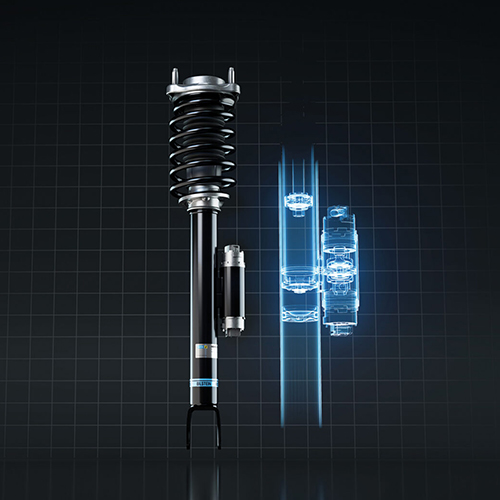

2,000 kilometres to the perfect shock absorber: How BILSTEIN tests its aftermarket products on the road

Before a shock absorber or suspension system is allowed to carry the BILSTEIN logo, it undergoes an intensive testing phase. And this applies not only to original equipment products that we manufacture for leading car manufacturers. Aftermarket products are also tested with exceptional care and tuned to specific vehicles as part of a development process that goes far beyond what is usual in the industry.

A central part of this work takes place in road tests, but above all on the demanding test tracks of the ‘Automotive Testing Papenburg’ test site in Germany. Renowned car manufacturers test their prototypes and concept cars here on a total of 780 hectares. Hermetically protected from the public and under the strictest confidentiality.

Papenburg: The test track for car manufacturers

On these tracks, future series products for the aftermarket are tested under a rigorous programme. For every vehicle model for which a BILSTEIN shock absorber will later be offered on the spare parts market, the suitable product is adjusted, tested and approved here specifically for that vehicle. Until the result is perfect.

‘On the secret test tracks of the automotive test site in Papenburg, each of our test vehicles covers up to 2,000 test kilometres. Perfect for thoroughly testing every aftermarket suspension and every shock absorber,’ reveals Stefan Pietzyk, Vehicle Dynamics Senior Engineer in BILSTEIN’s so called “Fahrversuch” — road testing department.

Every shock absorber and every suspension system is tailored to the specific vehicle

When you talk to Stefan Pietzyk, you immediately sense that there is a passionate professional at work. The automotive engineer has been working at BILSTEIN for almost two decades – a specialist who not only knows test benches, data and driving behaviour, but also understands them. And he knows what he is talking about. For over 15 years, the engineer with a background in mechanics has been part of BILSTEIN’s road testing, having developed countless vehicles and experienced how theory translates into driving experience.

Pietzyk: ‘Every vehicle that enters the driving test undergoes around a week of intensive testing.’ The routes in Papenburg alternate between cobblestones, high-speed sections and rough roads. Curves, potholes, load changes: ‘The driving test defines how a BILSTEIN suspension really feels,’ says Pietzyk. This is where the characteristic curve is created – the behaviour of a shock absorber or suspension that determines comfort, control and precision.

What is tested in BILSTEIN road tests later impresses on the road

What begins on test benches and in simulations finally comes to life here. ‘You have to be able to feel a characteristic curve. And that’s only possible in road tests,’ explains Pietzyk. Calculations and models provide the basis, but only on real asphalt you can see whether the damping really does what it’s supposed to do.

When BILSTEIN engineers ‘tune’ the characteristic curve, it’s not a metaphorical expression – it’s literally precision work: minimal valve changes, new settings, reinstallation, driving again. Several times a day. ‘We install, drive and test until everything fits,’ says Pietzyk with a smile. The suspension should not only function, but also feel right – in every corner, on every surface, at every speed.

‘What works for us will also work later in the workshop.’

In addition to the perfect driving experience, which is always the engineers’ top priority, this effort has two other decisive advantages: Firstly, ease of assembly and accuracy of fit can be checked directly. Secondly, potential problems are identified long before a product reaches the workshop.

emphasises Pietzyk ‘What works for us will also work later in the workshop and in your customers’ vehicles,’

This is not a marketing promise, it is the result of hundreds of hours of real testing.

BILSTEIN road test: Effort that builds trust

For workshops and motorists, this effort means one thing above all else: safety. Every BILSTEIN product is tested on the road before it goes into production.

Each component has been installed, tested and revised multiple times. Each characteristic curve has been adjusted until it perfectly reflects what the BILSTEIN brand stands for: control, precision and trust.

In BILSTEIN road tests, between cobblestones, high-speed tracks and speed bumps, the difference between a suspension and a BILSTEIN suspension becomes clear.

Our cutting-edge valve technologies and damping systems – from active to passive – guarantee unrivaled top performance and reliability. We bring premium OE quality to the aftermarket, making testing easier and ensuring your success every day.

Discover the technology