Where quality is engineered: How computer-aided engineering improves BILSTEIN shock absorbers and suspension systems

Quality in suspension systems does not begin on the road. Nor does it begin on the test bench. At BILSTEIN, it begins much earlier – on the computer. Mirco Adam, Senior Manager CAE at BILSTEIN, takes us behind the scenes and shows us how computer-aided engineering improves shock absorbers and suspension systems at BILSTEIN.

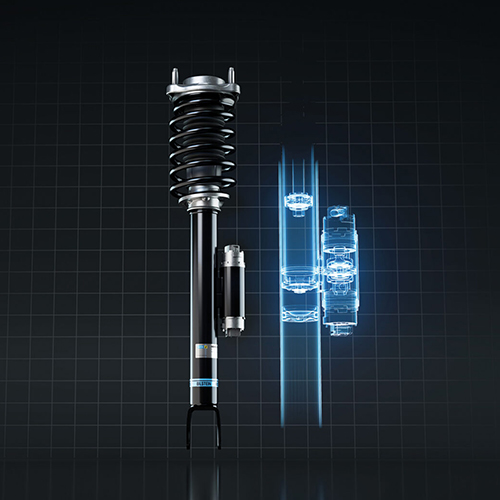

Computer-aided engineering, or short CAE, describes the computer-based simulation of technical systems. At BILSTEIN, this means that shock absorbers, suspension components and their interaction with the vehicle are digitally replicated. Forces, road surface vibrations, body movements, temperature behaviour, oil flow or continuous loads can thus be simulated virtually.

The crucial advantage: simulations provide insights that would be very difficult or impossible to obtain in the real world. Components can be specifically tested to their load limits – and beyond – without wasting material or risking test vehicles.

Computer-aided engineering at BILSTEIN: crucial for quality

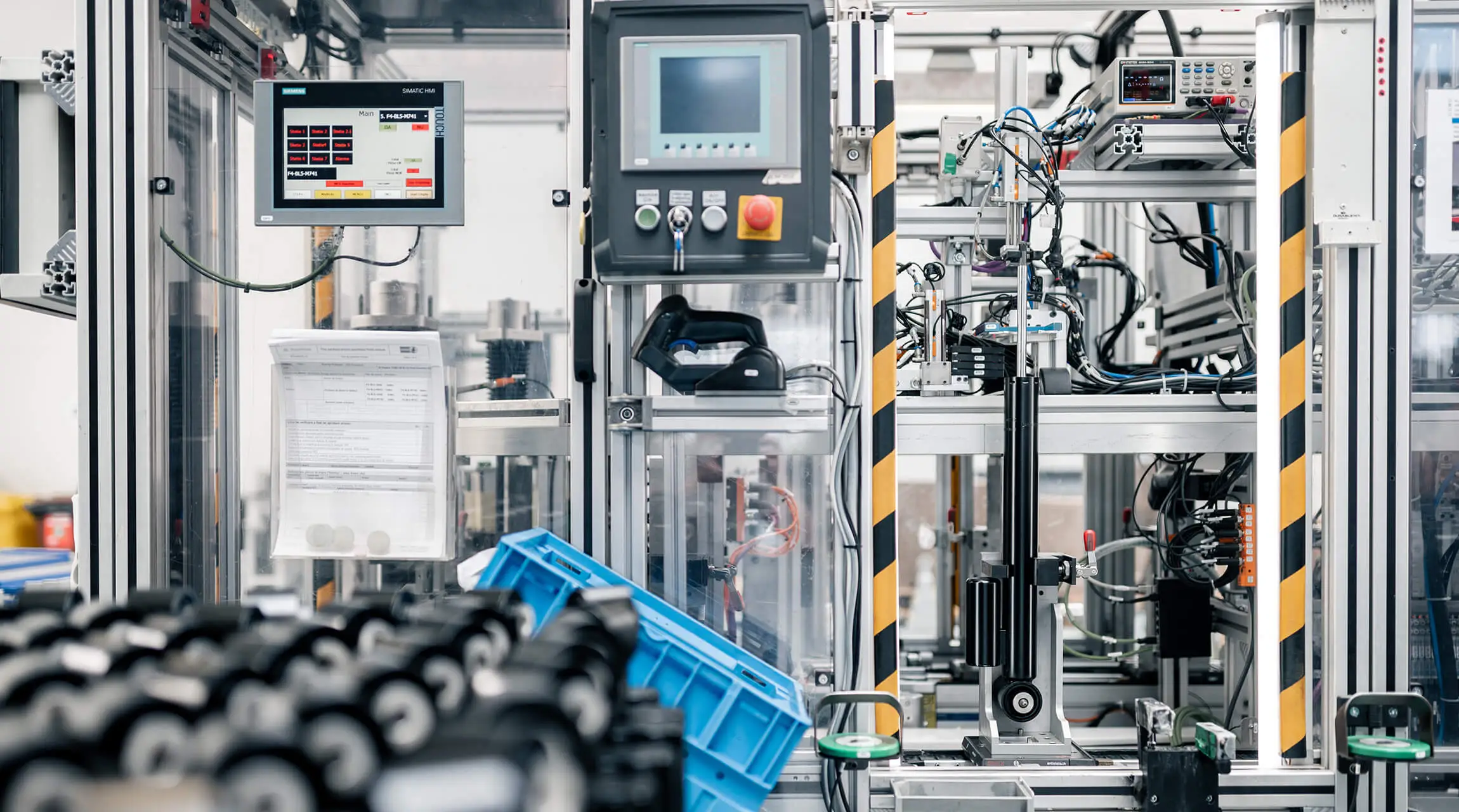

At BILSTEIN, CAE is not an optional tool, but an integral part of the development process. Before a shock absorber is manufactured, assembled or tested, it must prove itself virtually. Loads, forces, movements and thresholds are simulated, analysed and evaluated long before any real hardware exists.

Mirco Adam, Senior Manager CAE at BILSTEIN, reveals: ‘Simulations are an integral part of our development process. They show at an early stage whether a technical concept works, even before a component is built. At the latest, the series designs must be checked by simulation before hardware parts are ordered.’

CAE does not replace testing at BILSTEIN. It makes it more precise. ‘Despite CAE, it remains necessary to test components specifically to their limits in order to make reliable statements,’ says Adam. ‘This is the only way we know whether we would have predicted the failure. It is a continuous improvement process.’

Quality means understanding why something happens

One of CAE’s key contributions to quality lies in causality analysis. Individual parameters can be modified in a targeted manner in the simulation without disruptive external influences. ‘The advantage of simulation is that I have no disruptive conditions,’ says Adam. ‘When I change a parameter, I can see exactly what effect it has.’

For development, this means that instead of making assumptions, correlations can be clearly identified. Why does the damping behaviour change? Which load is really critical? Which changes bring measurable benefits – and which do not?

These findings flow directly into design decisions, valve tuning and component design.

Experience beats computing power

As powerful as modern simulations are, their significance depends crucially on the expertise of the people behind them. At BILSTEIN, CAE is therefore closely linked to decades of development and testing experience.

‘If parts fail unexpectedly, it’s our job to investigate,’ explains Adam. ‘This allows us to grow our wealth of experience. And we’ve been doing this for more than 20 years now.’

Every deviation, every real-world test, every field failure further refines the models. Simulation and reality evolve together – a learning system.

OE standards as a foundation – also in the aftermarket

A significant part of this wealth of experience comes from original equipment. The load assumptions, safety reserves and limit cases required by car manufacturers also form the basis for simulations in the aftermarket. ‘We draw on this experience,’ says Adam. ‘We know the requirements from the OE business and transfer them to aftermarket components.’

For workshops and motorists, this means that aftermarket products are also based on the same physical principles, the same limit considerations and the same level of safety.

CAE: Efficiency without compromising quality

CAE improves quality not only through depth, but also through efficiency. Simulations help to target testing efforts where they are really needed. ‘There are use cases where we can reduce hardware testing to the most critical variant in the simulation,’ explains Adam. ‘If this passes the endurance test, there is no need to test other variants that are less critical in terms of calculations.’ This saves time without compromising safety or durability.

Computing power as a quality factor

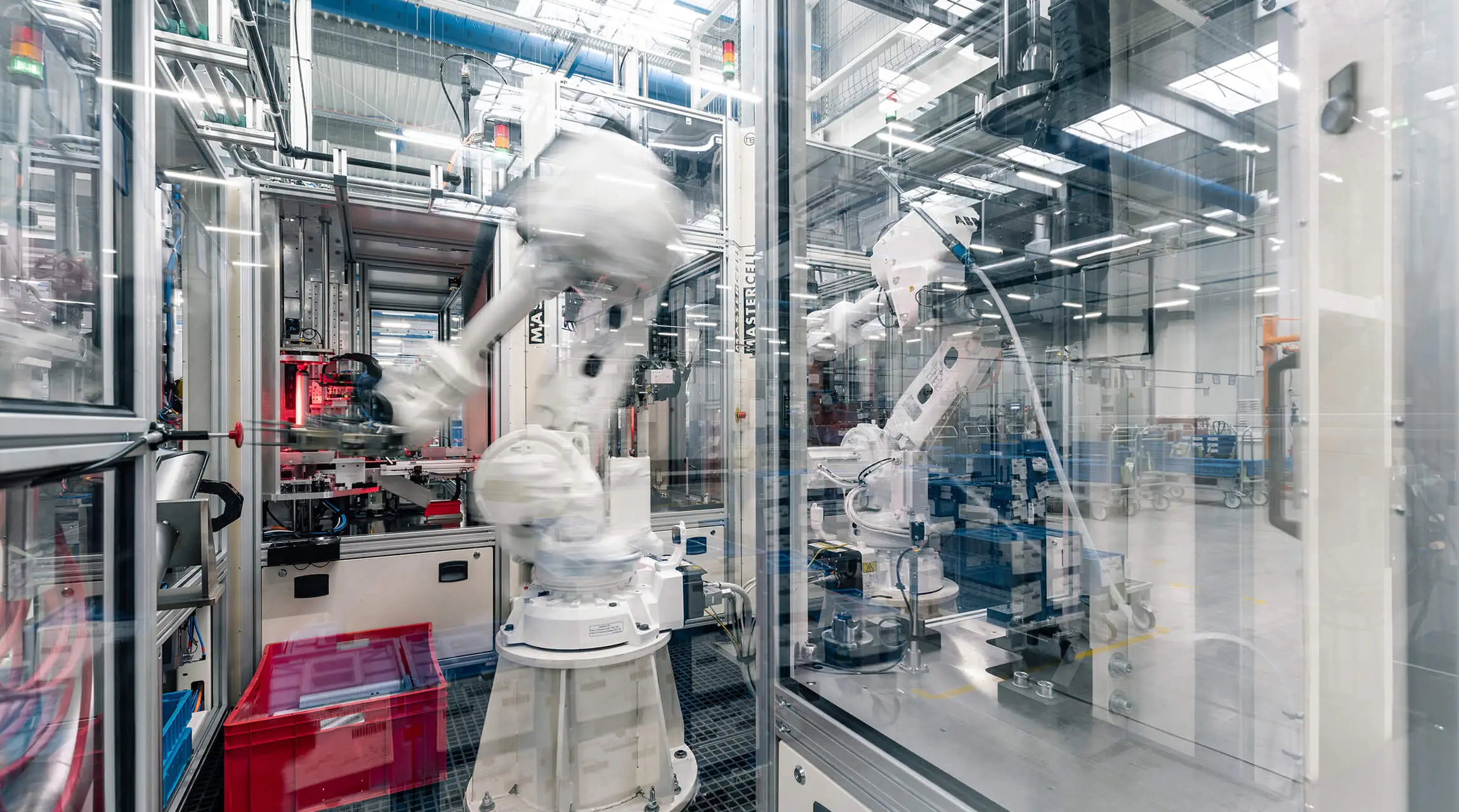

The effort behind CAE is considerable. High-performance computers run virtually around the clock at BILSTEIN. ‘There are simulations that run for 24 hours or even several days,’ says Adam. ‘In fact, our computers run 24 hours a day, seven days a week.’

This computing time is not just for the sake of it. It is the price to pay for reliable statements – and for decisions based on objective data rather than subjective assumptions.

Simulation, test bench and road testing – one system

Despite all the computing power, one thing remains clear: CAE is part of a system. Simulation, test bench and real-world road testing complement each other.

emphasises Mirco Adam. ‘Simulation and testing will always be interdependent,’

It is only through interaction that the quality for which BILSTEIN stands is achieved: virtually validated, tested in real life and refined over many years.

For motorists, workshops and dealers, this effort is not reflected in figures or models, but in driving performance. In shock absorbers that work in a controlled manner, react predictably and function reliably over a long period of time.

Our cutting-edge valve technologies and damping systems – from active to passive – guarantee unrivaled top performance and reliability. We bring premium OE quality to the aftermarket, making testing easier and ensuring your success every day.

Discover the technology