How BILSTEIN sets OE standards in the aftermarket

When drivers expect a premium driving experience, there can be no compromises. At BILSTEIN, this principle applies not only to original equipment, but also to the aftermarket. At the Ennepetal site, a highly specialised team ensures that shock absorbers and suspension solutions for workshops meet the same standards as products for Mercedes-Benz, Porsche or BMW.

Crucial to this is the Quality Management department at the Ennepetal site, headed by Dr. Vasilios Vasiliou. The engineer has been Quality Manager at the BILSTEIN site in Ennepetal since 2020. Vasilios obtained his doctorate at RWTH Aachen University before gaining experience at Bosch and ZF. With his extensive experience in research, industry and manufacturing, he now manages the company’s quality assurance at the Ennepetal site.

His department is responsible for the entire quality cycle: from new part sampling and series testing to the systematic analysis of complaints. The aim is to ensure that every product offers maximum reliability to automotive workshops, as Vasilios emphasises:

Dr. Vasilios Vasiliou ‘Our goal is clear: unpack, install, drive off – without worries and withoxut complaints.’

BILSTEIN invests extraordinary effort to achieve maximum quality

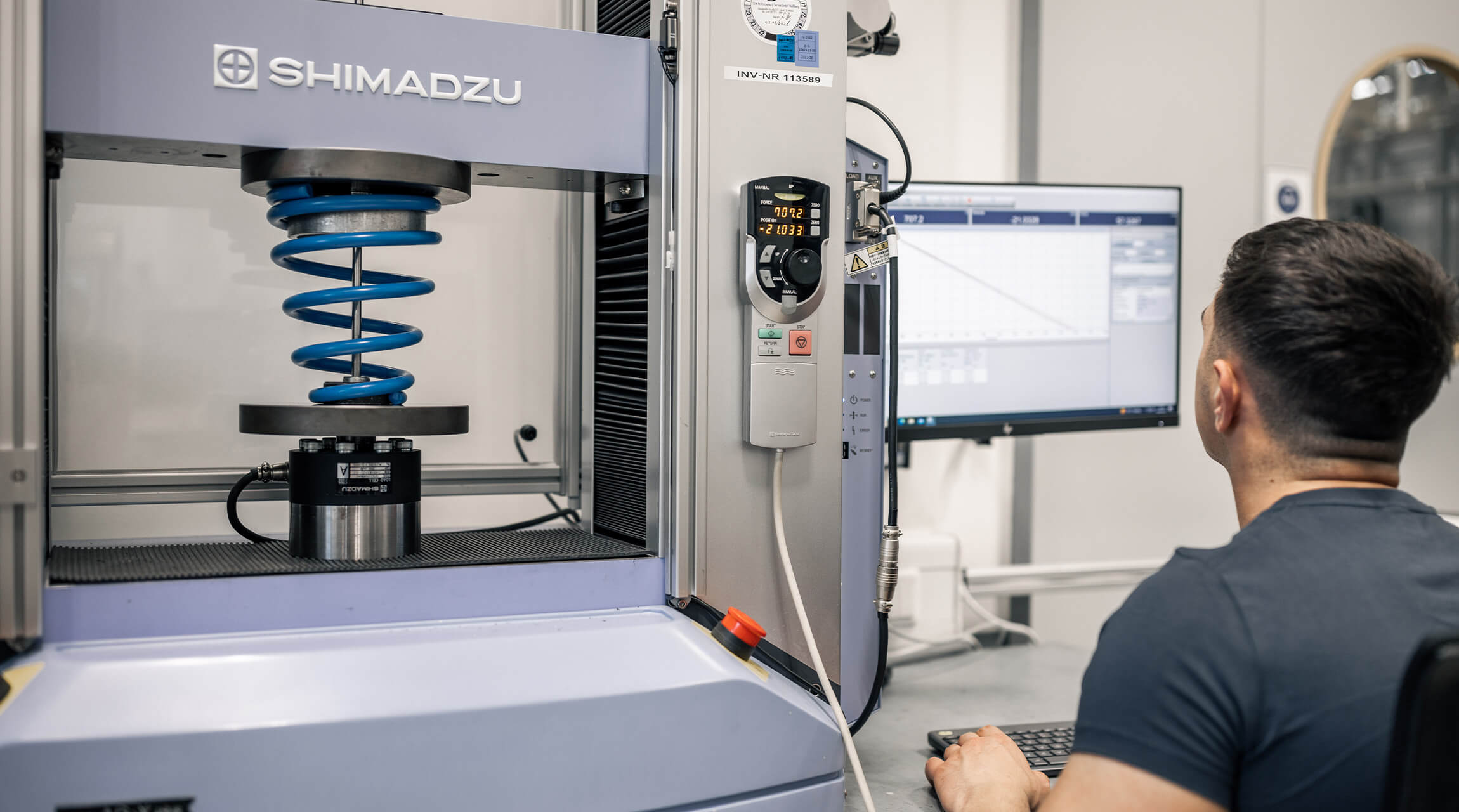

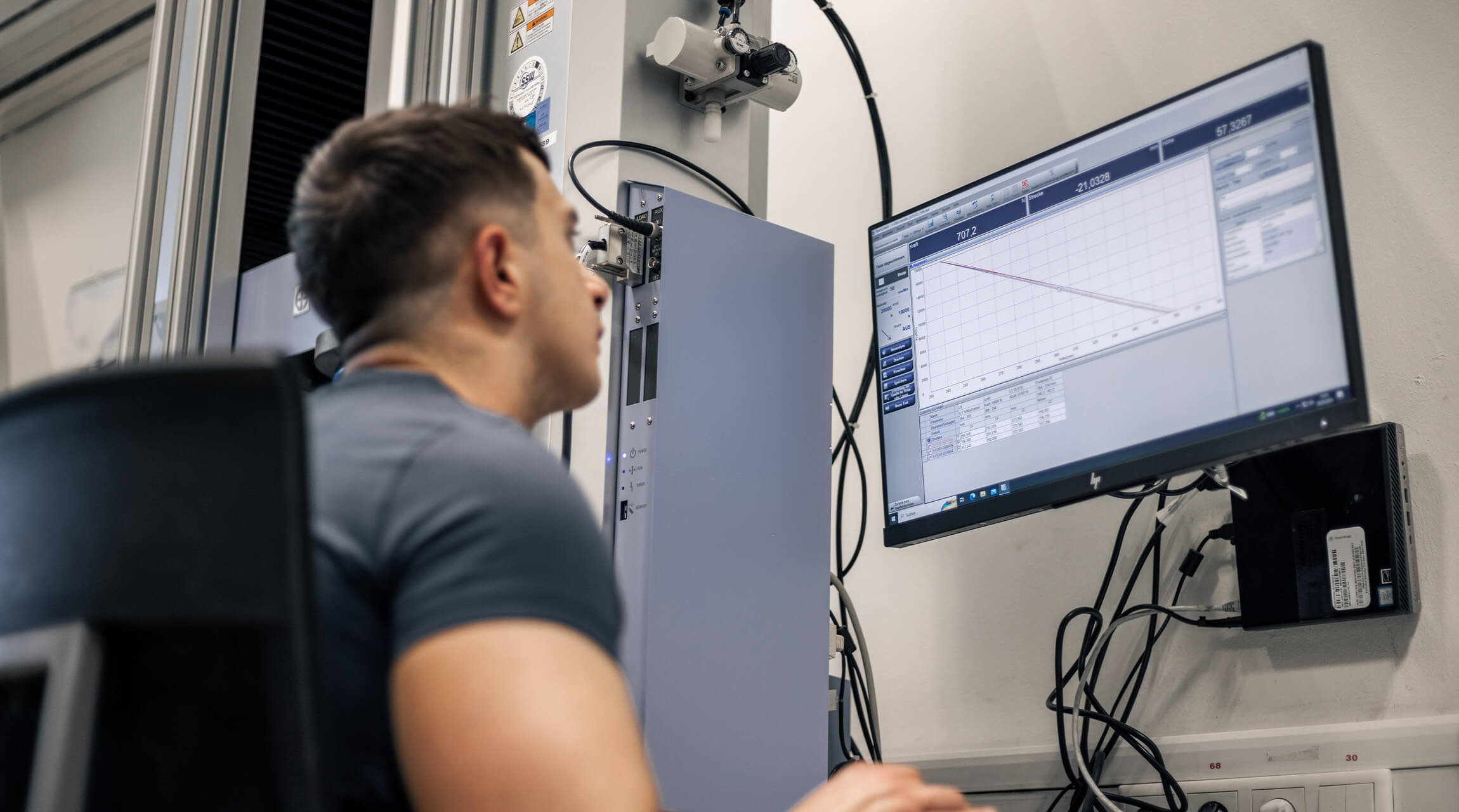

To achieve this, BILSTEIN invests maximum effort: the laboratories in Ennepetal operate in two shifts. Every week, over 100 measurement reports are produced in the measuring rooms. These cover four key test areas. Firstly, dimensional tests with 3D measuring machines and contourographs, which record dimensions and tolerances with micrometre precision. Secondly, material tests, in which hardness, tensile and compressive values and coating thicknesses are tested. Thirdly, corrosion tests in salt spray chambers, which simulate the resistance of various paint and zinc-nickel coatings. And fourthly, the evaluation of parts from the field, in which the causes are analysed and measures for improvement are initiated.

Complaint rate massively reduced

‘For us, a complaint is like an audit – always an opportunity to improve our products,’ says Vasilios. This consistent strategy systematically leads to significant progress – for example, in the optimisation of coating processes, which has significantly extended service life. And it is proving successful: ‘We have been able to further improve quality performance in recent years, which is reflected in very good customer feedback from the market regarding the quality of our products,’ says the quality manager.

Figures that speak for themselves

The extent of the effort can be seen in the figures. In the aftermarket sector alone, around 20 specialists are employed in measuring rooms worldwide to ensure the quality of BILSTEIN products for retrofitting. And while around 300 new parts were sampled in Ennepetal per year just a few years ago, today the figure is around 500. Over 25,000 measurement reports are produced every year – a figure that illustrates how consistently BILSTEIN works in detail.

Quality as a system

While many aftermarket shock absorber suppliers are only ISO 9001 certified, BILSTEIN deliberately goes one step further. Like all of the company’s production plants, the Ennepetal site is certified to IATF 16949. This standard is considered one of the world’s most demanding standards in the automotive industry and was developed for original equipment. It combines the particularly demanding requirements of international OEMs and specifies detailed requirements for processes, documentation and quality management. ‘IATF 16949 in the aftermarket is exceptional – we deliberately maintain the original equipment standard,’ emphasises Dr Vasiliou. For workshops and wholesalers, this means maximum safety and product quality that far exceeds the norm in the spare parts market.

Digitalisation as a driver

BILSTEIN also relies on state-of-the-art technologies for quality assurance. Tests that used to be paper-based are now carried out digitally using CAQ software, as is also used in the OE sector. Results are available immediately, and dashboards provide live data on complaints or deviations. This allows trends to be identified more quickly and measures to be taken at an early stage. ‘Before the workshop complains, we have long since found or ruled out the fault,’ summarises Dr Vasiliou.

Practical benefits

For independent workshops, this means less risk and greater efficiency. Shock absorbers from BILSTEIN can be installed quickly because they fit perfectly. Complaints are rare and rework is eliminated. At the same time, workshops benefit from the strong brand image: those who install BILSTEIN show their customers that they are committed to premium quality. For motorists, in turn, the quality is immediately noticeable – in terms of driving comfort, safety and durability. Reliable availability through wholesalers also ensures fast deliveries and short downtimes.

‘Our products are engineered to ensure safety in everyday use while maintaining the driving pleasure you expect from a premium vehicle,’ explains Dr Vasiliou. For him and his team, this means not only mastering processes, but also taking responsibility for the trust placed in them by workshops.

BILSTEIN demonstrates that quality in the aftermarket must be understood not as a promise, but as a daily reality. With state-of-the-art measuring rooms, an international network and a consistent approach to certification, the company builds trust among workshops and wholesalers. Or, as Dr Vasiliou puts it: ‘We want customers to install our product – and then simply enjoy. Because it just works.’

Our cutting-edge valve technologies and damping systems – from active to passive – guarantee unrivaled top performance and reliability. We bring premium OE quality to the aftermarket, making testing easier and ensuring your success every day.

Discover the technology