Where quality is born: A look inside the BILSTEIN materials laboratory

Quality is regarded as a standard in the automotive industry. But what does quality really mean beyond marketing promises and product claims? At BILSTEIN, quality is evident in the details. In processes that are consistently challenged. And in the willingness to take a close look. Even when components are no longer new. This story takes us exactly there. To BILSTEIN’s materials laboratory. And to a woman whose work is rarely seen, but who makes a decisive contribution to the quality made by BILSTEIN.

If something is wrong at BILSTEIN, sooner or later it ends up on Sarah Sangermann’s desk. Not always a complete shock absorber. Sometimes it’s just an inconspicuous component that seems harmless at first glance. Sarah takes a close look anyway. Because this isn’t about the big picture, but about components that are only a few centimeters in size. And about deviations that only become apparent under a microscope.

Sarah has been working at BILSTEIN in Ennepetal for ten years. What is now a highly specialized materials laboratory started with her and a few pieces of equipment. A stereo microscope, a hardness tester. That was all there was. “We used to have to outsource a lot of analyses. That often took weeks,” she recalls. Today, BILSTEIN deliberately pools this expertise in-house. This means shorter distances, direct exchange, and significantly faster response times.

“Our laboratory is like a small detective agency.”

Her work usually begins where others get stuck. When test engineers notice anomalies. When workshops complain about components. When field failures occur. And that’s worldwide. China, the USA, Europe: the origin doesn’t matter. The high standards do.

“Before I use measurement technology, I first form a picture in my mind,” says the state-certified materials engineer.

Sarah Sangermann “Our laboratory is like a small detective agency: we track down faults and investigate where they might have originated. In the material, in the weld seam, or in the application.”

Experience and analysis work together, step by step, until a clear picture emerges.

High-end materials technology

The team Sarah works in analyzes components down to areas of around 50 micrometers. They dismantle, compare, and examine. First visually. Then microscopically. Then even deeper. Fatigue fracture or material inclusion? Error in the hardening process? Welding parameters outside the tolerance range? Often, the cause lies in details that are only visible under a scanning electron microscope.

Up to 450 such analyses are carried out each year. Some take hours, others several days. The end result is not a gut feeling, but a detailed report. A technical assessment. A basis for well-founded decisions. “Sometimes we adjust parameters on the same day,” says Sarah. “This speed is a real advantage.”

Material analysis as a driver of further development

Above all, however, these analyses are a tool for further development. They ensure that findings do not remain in the laboratory, but are directly incorporated into processes. Into the selection of materials. Into the design of components. Into manufacturing parameters that ensure that BILSTEIN products function reliably for many years.

This is precisely where BILSTEIN’s in-house material expertise lies. While many competitors continue to rely on external laboratories, BILSTEIN deliberately focuses on its own in-depth and immediately available expertise. Results are available quickly, coordination takes place directly, and adjustments can be implemented at short notice. The laboratory is therefore not an isolated testing area, but an active part of quality and development work.

Material testing according to OE specifications

Sarah works closely with test engineers, quality management, and product development. Regular meetings ensure that her expertise is incorporated into new projects at an early stage, long before a product reaches the market. Decisions are not postponed, but made on a sound basis.

Of course, this work is done according to the strict original equipment standards of car manufacturers. It doesn’t matter if it’s for series products or aftermarket components. The standards stay the same. And that’s exactly what the aftermarket benefits from: the same depth, the same care, the same consistency.

Quality is continuously developed at BILSTEIN

What is now a small, highly specialized team has developed over many years. With growing expertise, modern equipment, and the ambition not only to keep pace with new materials and requirements, but also to actively shape them. Quality is not just managed here. It is continuously developed.

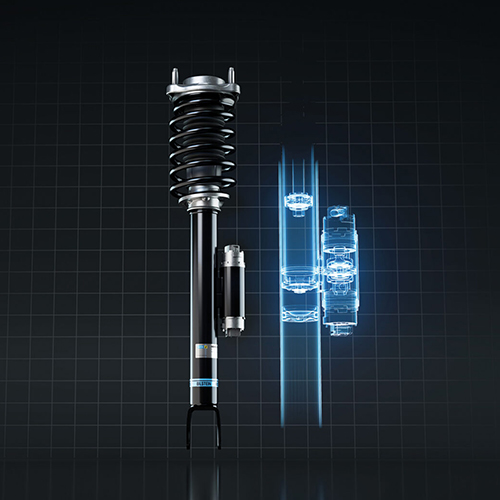

Our cutting-edge valve technologies and damping systems – from active to passive – guarantee unrivaled top performance and reliability. We bring premium OE quality to the aftermarket, making testing easier and ensuring your success every day.

Discover the technology