Quality according to OE standards: a requirement that also applies to the aftermarket

For years, partnerships with car manufacturers such as Mercedes-Benz, BMW, and Porsche have defined BILSTEIN’s quality standards. The company consistently applies these standards in the aftermarket as well: every new product for retrofitting – from series replacements to performance suspension systems – is developed, tested, and approved according to the same quality rules as an OE product. This level of effort is exceptional among competitors, as Lars Homner reports.

Lars Homner definitely knows what he’s talking about. For many years, he designed quality processes for original equipment at BILSTEIN. Now he’s in charge of global quality management for the BILSTEIN aftermarket. His understanding of quality is shaped by experience and consistency.

Quality at BILSTEIN: Part of the corporate culture

At BILSTEIN, quality is not an isolated process step, but part of the corporate culture. Quality requirements are not adapted to specific projects, but are defined uniformly across all areas. This is a way of thinking and working that shapes decisions in development, purchasing, production, and quality equally. Regardless of whether a product is intended for series production or the aftermarket. Quality is therefore not a downstream test point, but a consistent principle.

Quality standards from original equipment: consistently transferred to the aftermarket

“Quality does not happen by accident, it is the result of conscious planning, careful execution, and targeted thinking,” explains Homner. Accordingly, BILSTEIN relies on the same technologies, testing systems, and suppliers in the aftermarket as it does in original equipment. Many key components originate from OE projects, where they have already been extensively tested and approved.

Quality begins with design

“True quality begins with design, through validated OE components and proven technologies,” says Homner. BILSTEIN deliberately uses components in the aftermarket that have already been used in original equipment and extensively tested there. These components have undergone demanding service life and stress tests – in accordance with the test requirements demanded by automobile manufacturers in series production. This validated development status, the technical maturity level, is then specifically transferred to the aftermarket.

100 percent tested – without exception

All aftermarket products undergo a 100 percent functional test: “Every single shock absorber is tested,” says Homner. “We use the same test systems as in the OE sector.” An effort that pays off:

Lars Homner reports “Our products not only look high-quality – they are high-quality. And that is measurable.”

At BILSTEIN, quality is not based on subjective impressions, but on reproducible results that are comparable worldwide and consistently evaluated.

Globally organized, certified according to OE standards

This comparability forms the basis for globally coordinated quality management: Colleagues in central aftermarket QM work closely with the teams in the plants. Regular reviews, uniform key performance indicator systems, and global transparency ensure that anomalies are identified early and addressed systematically.

All BILSTEIN plants worldwide – including pure aftermarket locations – are certified according to IATF 16949. This standard was originally developed for original equipment and places the highest demands on processes, documentation, and traceability. Aftermarket-specific processes such as the industrialization of new spare parts are also fully integrated into this system. “This is exceptional in the aftermarket,” as Homner emphasizes.

“We want customers to rely blindly on every BILSTEIN product.”

Ultimately, it’s all about reliability. For workshops, for retail partners, and for drivers worldwide. BILSTEIN invests a great deal of effort in this area in the aftermarket. But that’s precisely what the company strives for: not just promising OE quality, but consistently delivering it – even in the aftermarket.

“We want customers to be able to rely blindly on every BILSTEIN product,” says Homner. “Not because it looks good, but because it has been proven to be developed and tested according to OE standards – and because it is measurably better than many competing products in numerous areas.”

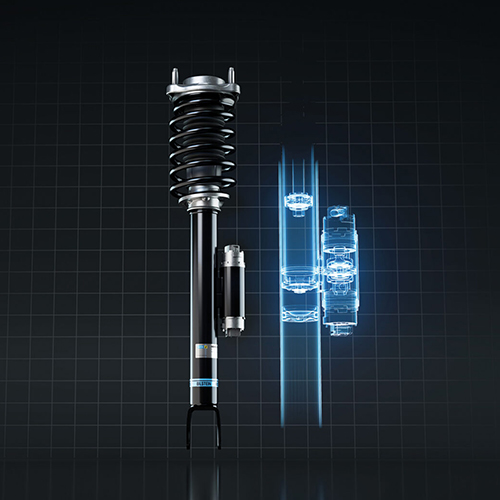

Our cutting-edge valve technologies and damping systems – from active to passive – guarantee unrivaled top performance and reliability. We bring premium OE quality to the aftermarket, making testing easier and ensuring your success every day.

Discover the technology