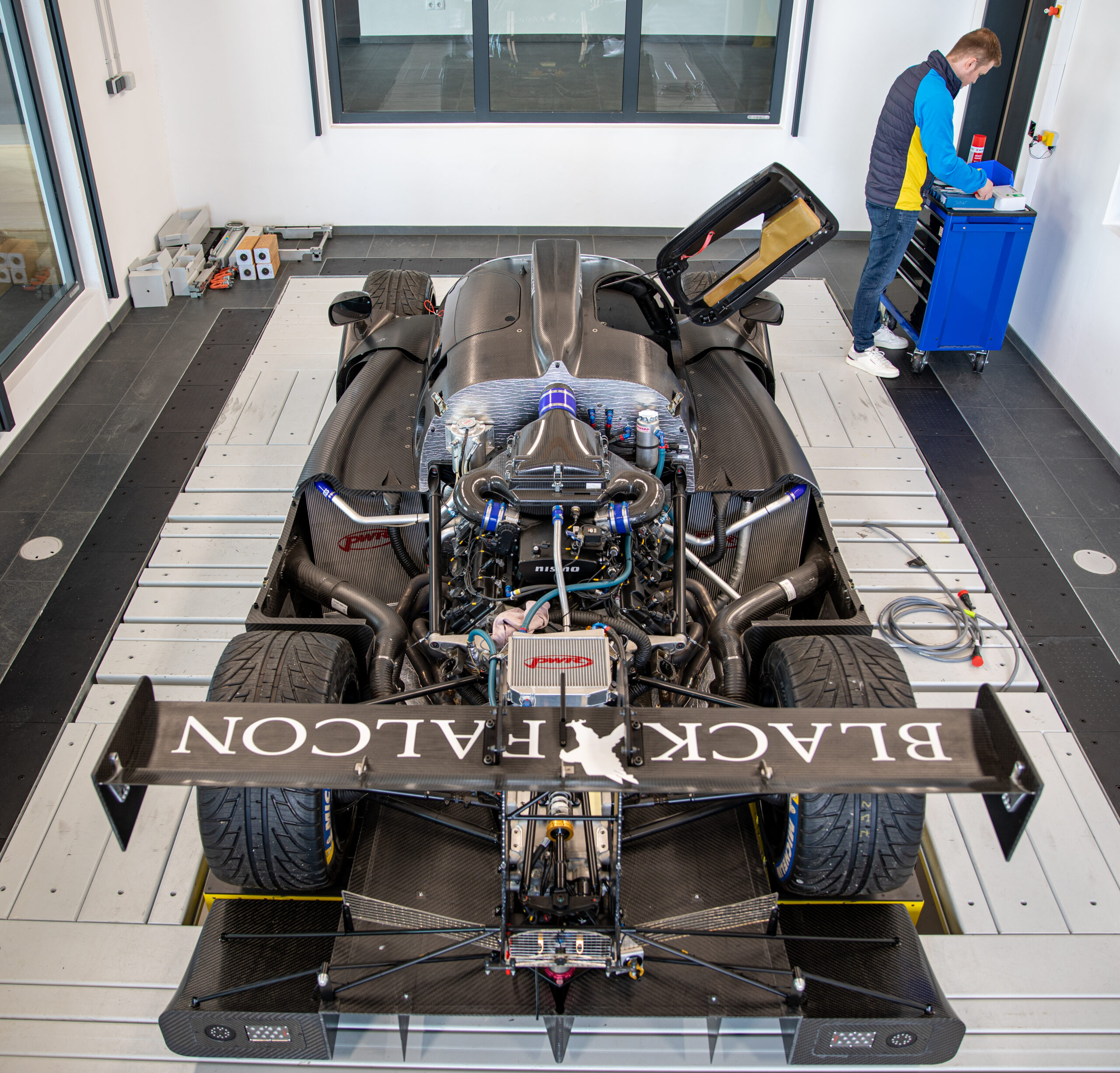

BILSTEIN’s New 7-Post Test Rig Fully Operational at Nürburgring Testing Facility

The new BILSTEIN 7-post vertical dynamics automotive test rig has been installed at the famed Nürburgring race track testing facility and is now fully operational. Also known as a multi-post rig or shaker rig, this advanced testing system will be utilized by BILSTEIN to evaluate and optimize the suspension performance of vehicles.

The test rig consists of a sturdy frame structure with seven hydraulic actuators strategically positioned. These actuators simulate the vertical motion experienced by a vehicle’s wheels when driving over bumps, potholes, or other irregularities on the road.

The test rig offers several testing modes allow BILSTEIN engineers to evaluate different aspects of suspension performance. Modes include:

- Ride Comfort Testing: This mode focuses on assessing the vehicle’s ride quality by subjecting it to various road inputs, such as sinusoidal bumps, step inputs, or rough road profiles. The test rig replicates these road conditions to evaluate the suspension’s ability to absorb and isolate vibrations, minimizing the transfer of harshness to the vehicle’s occupants.

- Handling and Stability Evaluation: In this mode, the test rig simulates dynamic maneuvers, such as cornering, lane changes, and sudden steering inputs, to analyze the vehicle’s handling and stability characteristics. Engineers can assess parameters like body roll, understeer/oversteer behavior, lateral grip, and the responsiveness of the suspension system.

- Suspension Tuning: The test rig allows engineers to fine-tune the suspension settings by evaluating the effects of different suspension components. They can analyze the performance impact of modifying shock absorbers, springs, anti-roll bars, bushings, or other suspension elements and optimize the suspension’s behavior for improved comfort and performance.

- Durability Assessment: This mode involves subjecting the vehicle to prolonged and repetitive road inputs to evaluate the durability and structural integrity of the suspension components. By simulating realistic road conditions, manufacturers can identify potential weaknesses or fatigue issues and make necessary design improvements.

- Tire and Wheel Testing: The test rig can also be used to evaluate the performance of tires and wheels. Parameters such as tire contact patch, load distribution, tire loads, and wheel forces can be measured to assess tire behavior, traction limits, and the impact of different tire and wheel configurations on overall vehicle performance.

- Active Suspension System Testing: If the vehicle is equipped with an active suspension system, the test rig can simulate various control strategies and evaluate their effectiveness. This mode allows engineers to analyze the response of the active suspension system to different inputs and optimize its performance for enhanced ride comfort and handling.

- Parameter Sensitivity Analysis: Engineers can use the test rig to analyze the sensitivity of suspension performance to different parameters such as spring rates, damping coefficients, or anti-roll bar stiffness. This mode helps identify the optimal parameter values that achieve the desired suspension behavior.

By utilizing a 7-post vertical dynamics test rig, BILSTEIN will be armed with valuable insights into the performance and behavior of the suspension system and can significantly accelerate the suspension development process for our OE partners, customers, and Motorsports teams.